The Australian construction industry is a major contributor to the national economy as a growing population necessitates the building of residential housing, commercial buildings, social spaces, and infrastructure. This demand has put greater pressure on builders, designers, and architects to reduce environmental impact during construction and to provide better performance over longer building lifespans.

Cross-laminated timber or CLT is at the forefront of this shift and has become synonymous with sustainability as a renewable resource and its low carbon footprint. If you too are considering using CLT in your new project then it is worthwhile to review what benefits CLT offers in terms of sustainability and environmental conservation. This blog is a comprehensive guide by The Rubix on CLT- what it is, how it differs from traditional construction materials and its sustainability status.

An Overview of Cross Laminated Timber

Cross laminated timber or CLT is a widely used engineered wood product which is manufactured by glueing layers of kiln-dried timbers together. The layers of timber are glued perpendicular to each other adding to its structural integrity and strength in both axes. CLT is being used rigorously in Australia for both residential and commercial projects.

Its rising popularity is a testament to the shift towards a better environmental awareness. In addition to this, CLT offers many other advantages over traditional construction material including its cost-effectiveness, durability, and design flexibility. This rising popularity is expected to grow further with better and more frequent domestic collaborations between architects and builders.

How are CLT Panels Made?

The cross laminated timber panels in Australia are generally sourced from plantation grown Pine particularly Pinus radiata. The manufacturing of CLT panels involves the following steps:

- The timber is kiln-dried to retain a moisture content of approximately 12%.

- The timber boards are finger-jointed to create longer boards and then left to cure.

- The CLT lamellas are assembled by placing the boards side by side, forming a solid timber layer.

- Each layer of the CLT panel is glued perpendicular to the last using structural adhesive.

- The panel is then pressed together with a hydraulic press.

- The CLT panels are then cut using a CNC for any openings or holes.

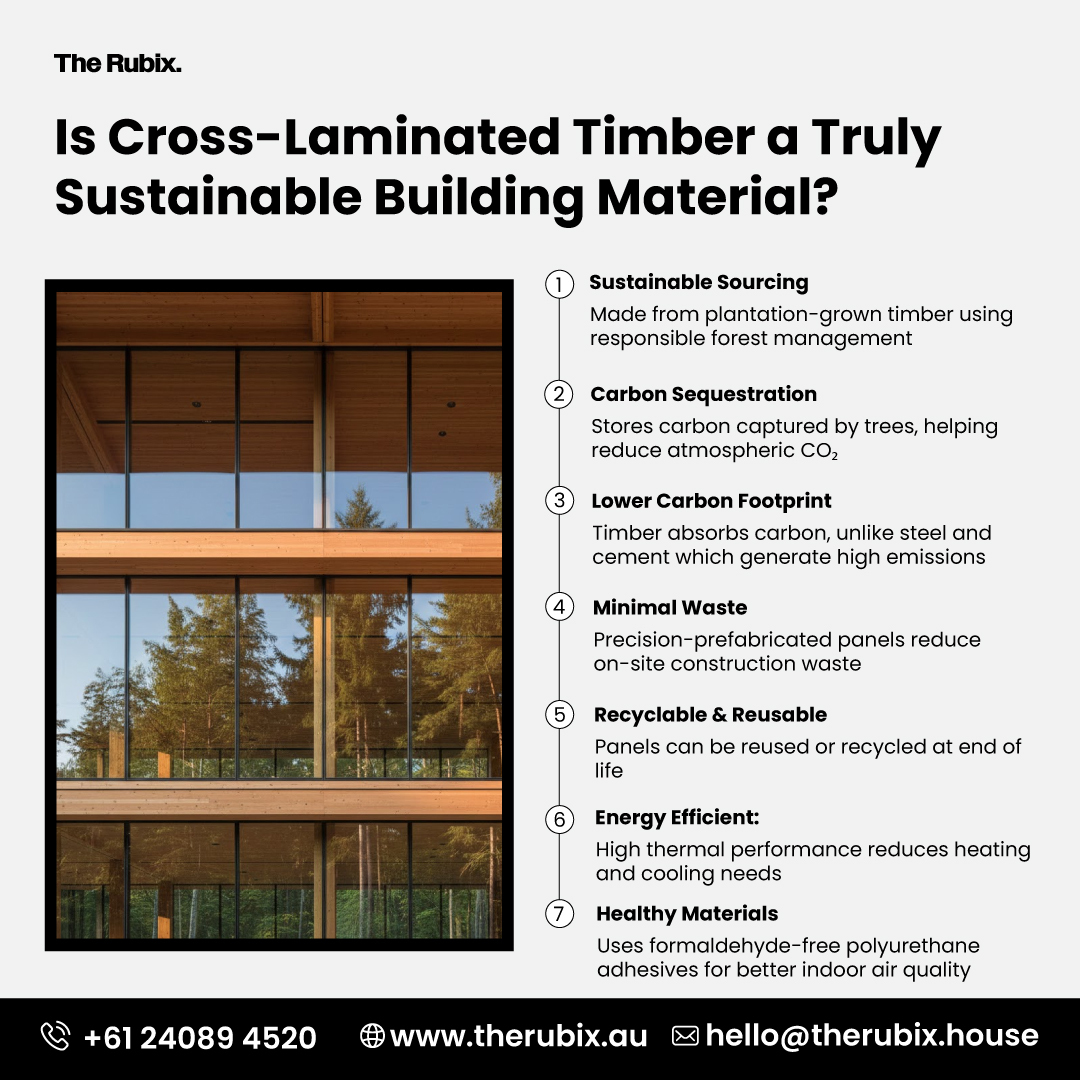

Is Cross Laminated Timber Really Sustainable?

CLT did not become popular purely for its sustainability credentials, (you can find those other reasons here), though it is a major driver behind its adoption. Here’s why:

Sustainable Sourcing

CLT is typically manufactured from plantation-grown timber, making it a renewable resource with responsible forest management.

Carbon Sequestration

Trees (especially young trees) sequester carbon out of the atmosphere during their lifetime. Too much carbon gas in the air is damaging to our climate, but carbon in solid form poses no environmental risk. When trees are cut down to make CLT they don’t release any carbon but continue to hold on to it. This conversion of gas carbon to solid carbon and the way the CLT industry contributes to the turn-over of young efficient trees in the plantation (rather than letting trees grow to inefficient old forest timbers) aids in the fight against climate change by reducing carbon in the atmosphere.

Reduced carbon Footprint

While Timber works to remove carbon from the atmosphere, cement and steel contribute to 17% of world-wide emissions. To put that in perspective, if the steel and cement industries were a country, they would be the third-largest emitter behind China and the U.S.

Minimal Waste Generation

The prefabricated panels of CLT are precisely engineered, this minimises the on-site waste. Further reducing the environmental footprint of such construction projects.

Recycling/Reuse

CLT panels can be recycled or reused at the end of their lifespan, this minimises its environmental impact further.

Less Energy Consumption

CLT has a high thermal efficiency and an ability to easily create air-tight structures. This means in comparison to conventional homes, a cross laminated timber house requires far less energy for cooling and heating.

Formaldehyde-free Adhesives

The adhesives used for CLT manufacturing are primarily Polyurethanes. Their strong bond and formaldehyde free formulation ensures sustainability and good indoor air quality.

Takeaway

In many construction projects, sustainability comes at the expense of cost or build speed. That trade-off is often accepted as part of doing the right thing. CLT is different in that respect. It delivers clear environmental benefits without slowing construction or driving costs higher. Speed, budget, strength, durability, and design flexibility are all maintained while reducing carbon footprint, and sequestering carbon. CLT has become the prime choice for a sustainable and environment friendly construction material.

Planning Your Next CLT Project?

CLT is a relatively new construction material in Australia, which is why it is important to partner with seasoned architects and building designers when building a CLT house. At The Rubix, we have a special team of CLT experts who excel at designing modern single and dual-occupancy CLT homes that reflect not just your sustainable choices but is a safe place for you and your family. Contact here to design your CLT house with us!